This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

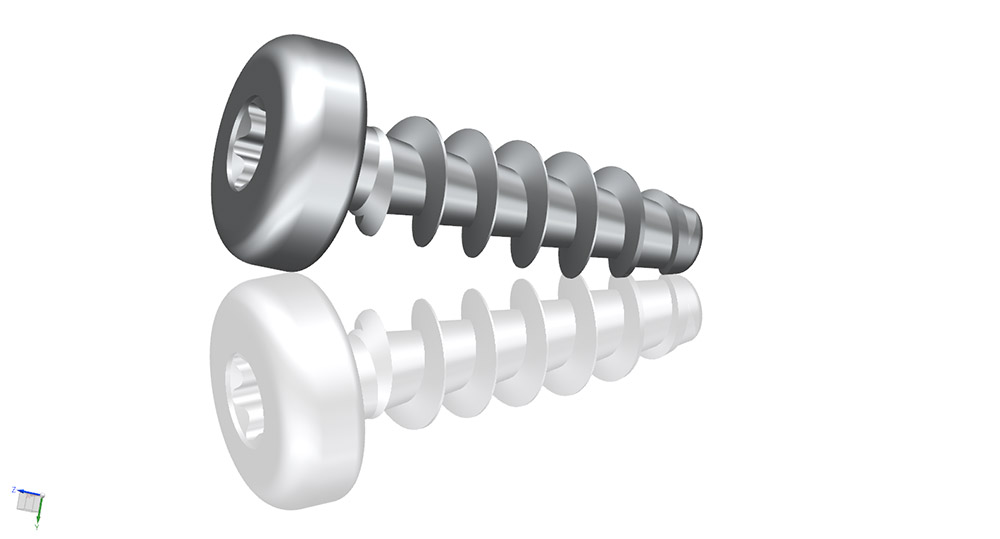

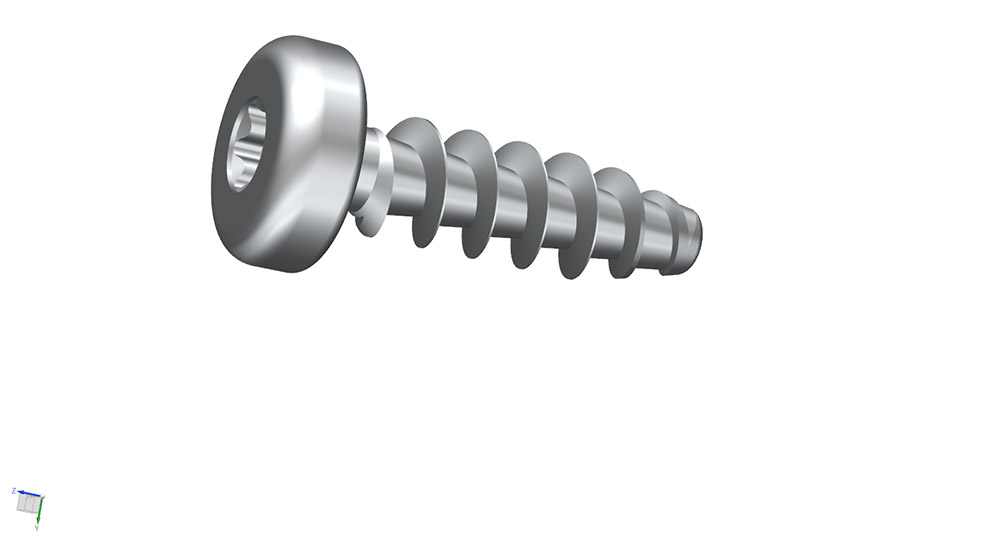

Schriever STS®

STS® – Your professional for connection with thermoplastics

Light – proven – minimum material stress

In brief

Connections made of thermoplastic materials are often associated with special challenges in the design, assembly and handling – this is now a thing of the past. We made the solution of this problem our task and with the Schriever STS® screw we found the ideal connection for professional use.

STS® advantages

- ideal connection of thermoplastics

- minimum radial stresses

- high load-bearing capacity

- lower thread molding torques

- eliminating the risk of relaxation

- no material degradation

- optimal self-locking effect

- cost-effective

At a glance – comparison between WN and KN | 100% compatible

| Schriever KN STS® | WN PT |

|---|---|

| 1031 | 1441 |

| 1031 neu | 1411 |

| 1032 | 1442 |

| 1032 neu | 1412 |

| 1033 | 1443 |

| 1033 neu | 1413 |

| 1034 | 1444 |

| Schriever KN STS® | WN PT |

|---|---|

| 1035 | 1445 |

| 1036 | 1446 |

| 1037 | 1447 |

| 1038 | 1451 |

| 1039 | 1452 |

| 1040 | 1453 |

| 1041 | 1423 |

The special part about it…

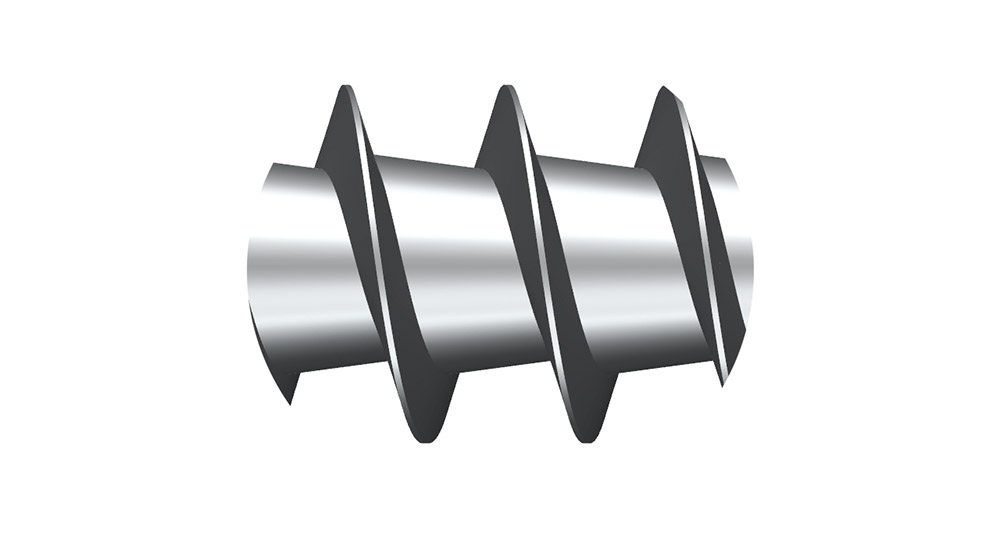

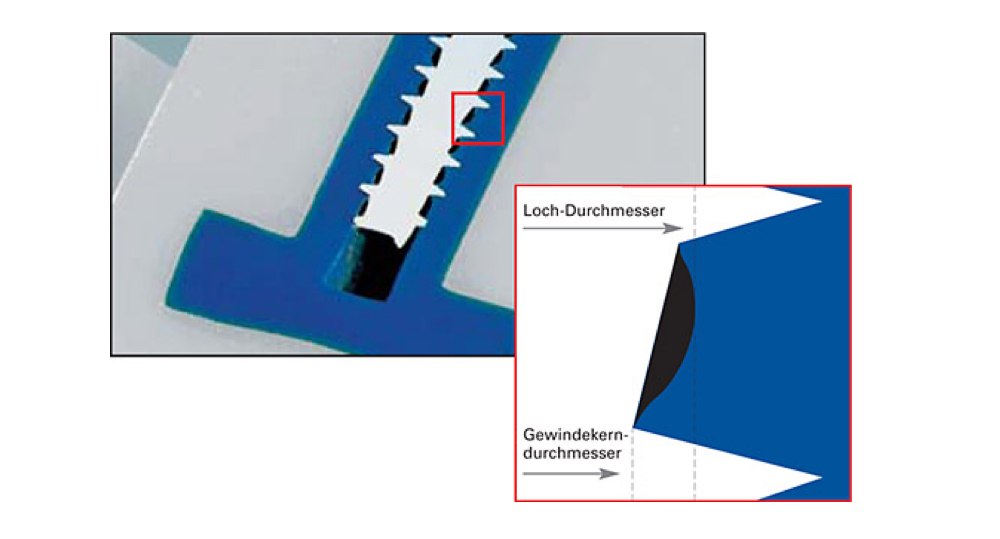

... vectorial characteristics

- Small radial forces – low radial stress

- Compared to conventional thread flanks with 60° (for example, self-tapping screws), our 30° flange angle reduces radial stress.

... Corrosion protection

Our screws can be made with all commercially available corrosion protection surfaces. For details, please refer to our brochure on corrosion protection which you can download here.

Offer concept S-connection

- Individually produced for you

- Available from a minimum quantity of 10,000

- Already available from four weeks on

Our service for you

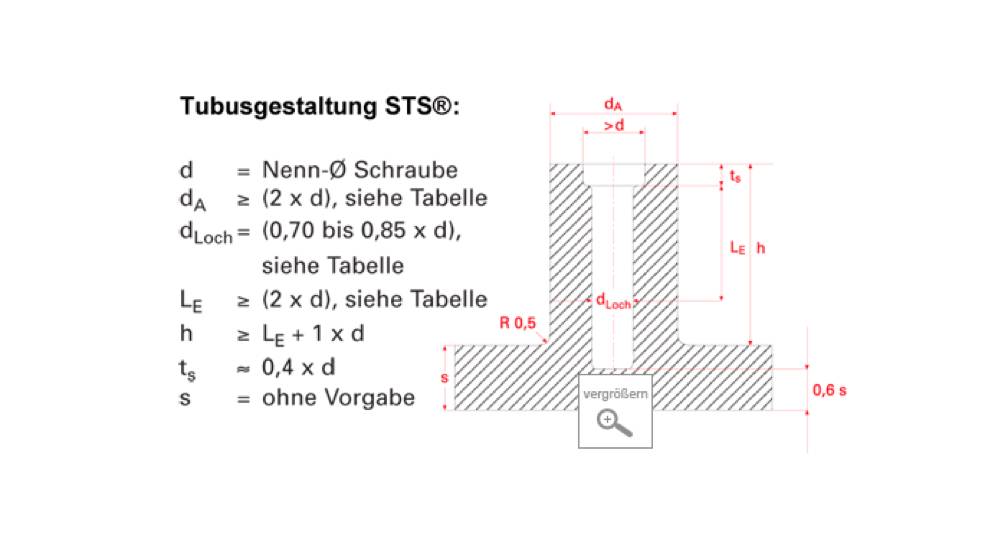

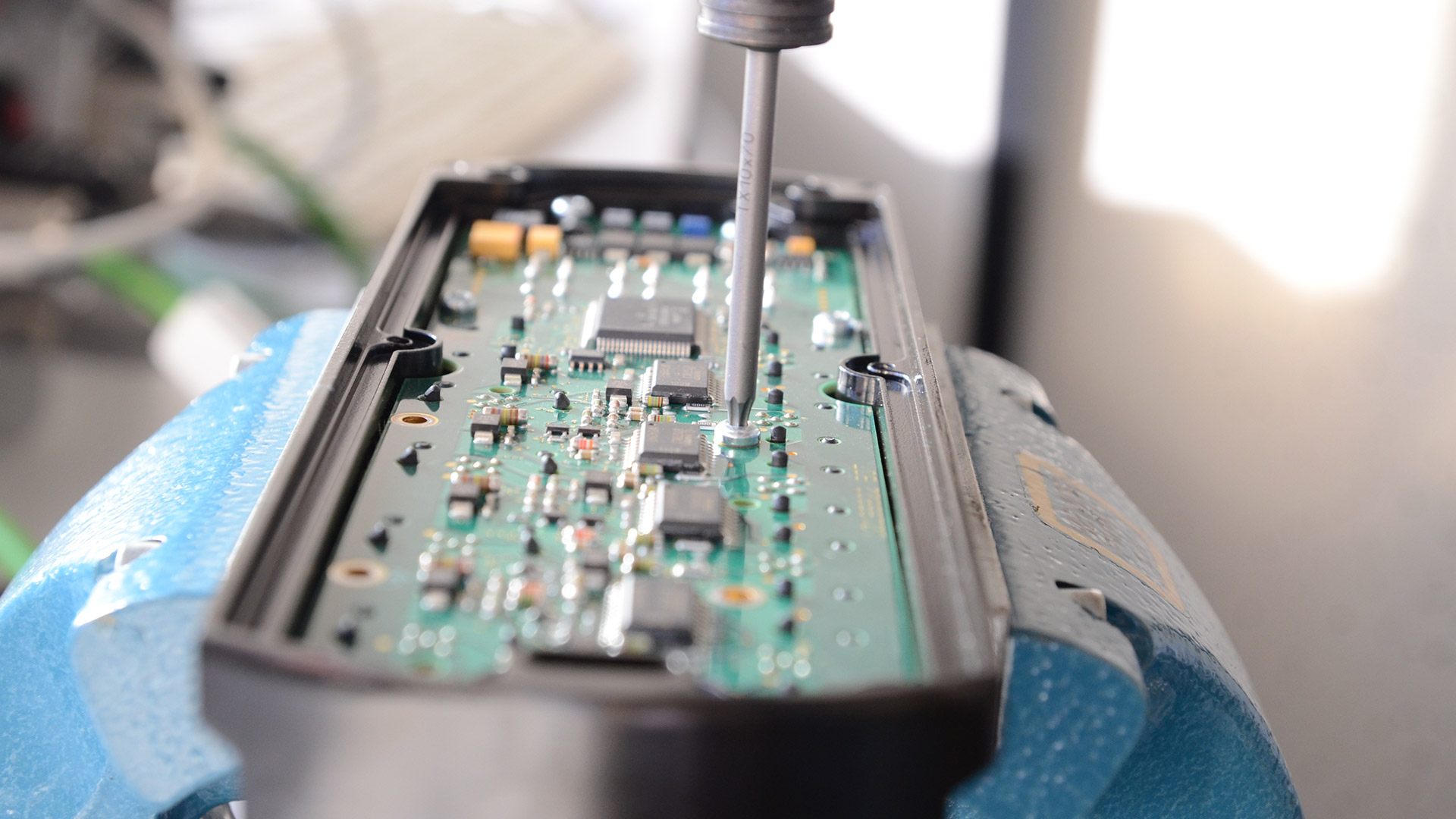

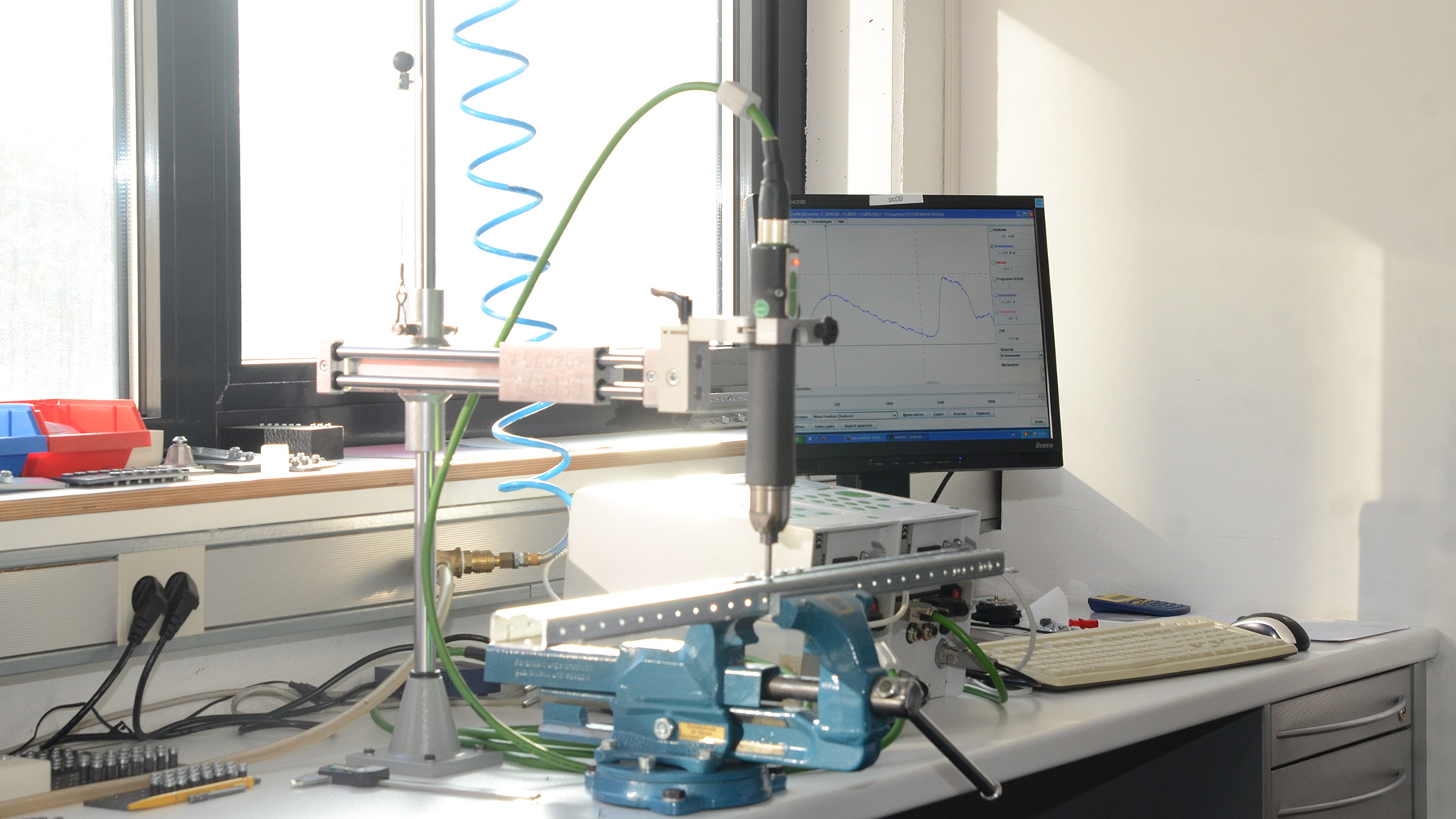

Experts & laboratory

At our testing laboratory, we optimize your joint applications and develop design recommendations. You will then receive technical documentation from us.

Order example:

STS® with nominal diameter = 3.0 mm · length = 12 mm · head = KN 1031 · drive Pozi drive = KN 1031 STS® 30 x 12 -Z

English

English

Deutsch

Deutsch